Or The Day I became a "1RV"

So, 3½ months later – the bulldozer has been and gone – as has the original Station Villa! Actually what's good is that there is now an extension on a barn conversion near Nantwich using the bricks. The roof tiles and timbers have all gone elsewhere.

I learned that by digging holes, I could claim to be referred to as a "1RV" Apparently before mechanised diggers (JCBs) first started to be used, a "2RV" was the workhorse crane that all the builders used. A man with shovel was therefore called a 1RV.

It's been an exciting and occasionally scary period. After the initial exhilaration wore off, the magnitude of the task of project managing the build of our own house started to dawn on us.

#Decisions

One of the first things we underestimated was how many decisions had to be made – and how many things we knew nothing about. For example, there are dozens and dozens of different bricks!

Then once you've decided on one (and asked the planners to approve it), you then have to decide on the colour of the mortar and how you want the pointing to be done – flush, bucket handle, recessed (and by how much).

I never expected to sit with Chris one evening, reading brick catalogues and discussing the merits of tumbled versus wire cut!

We have met many friendly people in process of making some of the choices – we knocked on the doors of several recently built houses and asked the startled inhabitants what make of bricks/windows/render it was built of! One kind chap even gave me a brick sample to take home!

#Timber Frame

One major decision was the decision to build the house using a timber frame – the English really do love traditional brick and block – unlike most other countries in Europe including Scotland. To our minds, the advantages of the high level of insulation we could achieve, the speed of construction, and, unlike a traditional brick and block method, a much simpler process for us to manage.

After much deliberation and discussion with many suppliers, we chose a local company down near Telford – Timber Kit Solutions (TKS). Of the many lessons that we've been learning, one of them is that it can be quite beneficial to deal directly with the people who own the company – our project manager on the construction is also the MD – decisions get made very quickly!

Several people have asked me about "that German kit house". I realised that this is because I had previously mentioned 'Passive House' – which is actually a German design standard for very low energy houses that requires no additional heating other than that created by solar gain through the windows, human bodies and cooking/lighting.

We're not quite that good, but have designed a 220m2, 4-Bed house that only needs a 4kW heat pump to keep it warm when it's -3C externally.

#Insulation

We've achieved this through masses of insulation, triple glazing and a heat recovery ventilation system – this recycles about 85% of the internal airborne heat to warm incoming fresh air.

These days, Building Regulations specify that you must build a house that is quite airtight – but then understandably demand that a certain amount of fresh air ventilation take place. The normal solution is to have 'trickle vents' on all the windows. To us it seemed intrinsically wrong to spend £1000s on expensive triple glazed window units that have holes to let in a draught!

#Fun

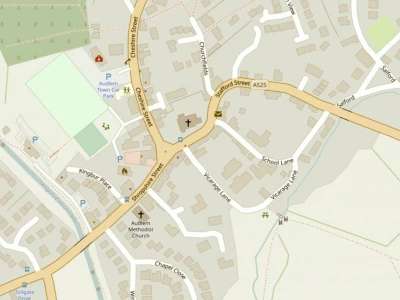

It is great fun as well. The bigger the project, the bigger the toys. Driving through Audlem in a 7 tonne, bright yellow Tonka tipper truck – complete with flashing light – was definitely a high point (for me)!

As you can imagine there have been quite a few ups and downs since the old house was reclaimed:

- the ground was deemed to be 'good and firm' for the foundations – but then we unearthed an old well about 2.5m deep, that cost us quite a bit in sweat, steel, concrete and structural engineers before we could start the foundation blockwork above it.

- the 100m deep borehole for the ground source heating became 2 x 50m deep ones after the drilling team found 'salt voids' at 55m! I tried to convince AudlemOnline to run an article on "Shale Gas exploration at Copthorne", but the editors didn't want to worry people too much – remember what happened when War of the Worlds was first broadcast!

- You realise just how skilled tradesmen are. Being lowered into a well to empty out the mud whilst standing in the bucket of the digger did require me to have a modicum of confidence in the driver's accuracy!! You also realise just how physically demanding the building trade is.

- Seeing the 3D model of how the house was to be constructed was amazing – it took on a new reality. When our architect initially suggested that the house should be split level to take advantage of the sloping site, it seemed like a really good idea.

That, coupled with our desire to have a fairly open plan house with vaulted ceilings and an 'Arts & Craft' design using mixed rooflines resulted a house that in the words of the 3D design engineer was – 'an interesting challenge' and 'actually it's the most complex house design I've ever worked on'. Hmmm!

- Working closely with a good builder/friend who thankfully took responsibility for all of the foundation work. Timber frame construction requires very tight tolerances – a maximum of 10mm difference in levels is all that they allow – and for a floor area of 110m2 on a sloping site with a complex shaped footprint, this is not a simple challenge. The MD of TKS came to do his laser survey foundation check prior to the build and was highly complimentary about the accuracy – big smiles all round!

- I learnt some new skills – mostly involving lifting heavy objects or using a shovel. It was so exciting when I had to pour liquid cement using a watering can, to fill in all the joints in the beam and block floor. Whilst performing this task I calculated that there was almost 600m of jointing – that's a lot of watering cans!

- A major highlight has to be the day that the crane raised the main steel portal that supports the entire front of the house – it's 9m high and weighs about a ton! It looks a bit like a cathedral when you see it on the hillside – it should look much better once the roof covers it!

One unexpected event was receiving an email from TKS asking us if we'd be interested in participating in a new Channel 4 TV series on self-build projects – a story already covered on Audlem Online

I think they knew that TKS had recently donated some wall panels for an extension as part of the 'DIY SOS' programme.

We're sure it will prove to be fun – and we've already had some very valuable advice from Charlie that has both improved the design and saved us money.

#Challenges

So the next set of challenges is for us to finish the frame, get the roofers to put the slate roof on, hopefully get the solar PV installed before the tariffs drop again, get the brickies in and finally have some windows installed.

There are still numerous construction issues to get sorted as to how we actually achieve some of the design features, but hopefully not too many issues – I have to admit that I do sometimes wake up in the wee small hours thinking about things that need doing and wondering how to organise them.

We then plan to have a holiday (hopefully a dry one) before starting work on the inside.

(You can click on the link below the photos to a PDF file with more photographs of this project.

If anyone wants to talk to Chris & Steve or are interested in a visit to see the work in progress, they are welcome to contact them via the AudlemOnline website.)

This article is from our news archive. As a result pictures or videos originally associated with it may have been removed and some of the content may no longer be accurate or relevant.

Get In Touch

AudlemOnline is powered by our active community.

Please send us your news and views using the button below:

Email: editor@audlem.org