Audlem area test for baler14 Sep 2015 6:06am: Webteam

If you have seen this baler locally, then you have witnessed a new piece of farm equipment being tested around Audlem despite it being developed in Italy.

A recent edition of Farmers Weekly featured the Vicon baler on its front page after a visit to this area.

Their report said: Farm machinery makers may have brought us all manner of reliable and effective kit over the past few decades, but there are some things that are proving difficult to design.

And one of the toughest nuts to crack is a round baler that can make a bale and wrap it – and do it without stopping.

Vicon's Fastbale was designed and developed at parent company Kverneland's baler centre at Ravenna in Italy.

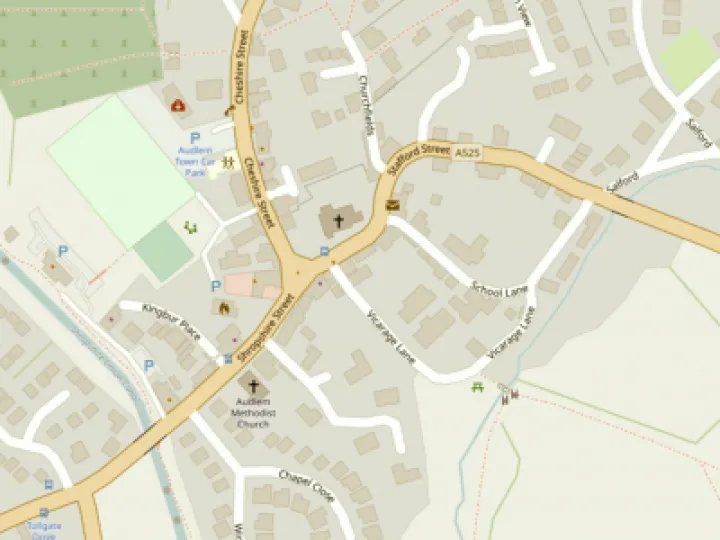

Machines are being tested around Europe, says Vicon's sales manager David Furber – note the local connection – particularly in the UK where heavy grass crops work the machines hard. Hence a press visit to Cheshire. (The report said Nantwich but it was indeed Audlem!)

How does it work?

On normal balers, there's typically a delay of 15-18 seconds while the bale is stringed and the wrap applied. However, with non-stop baler-wrappers, there's no delay at all – you just keep going.

Key to the design are the two chambers, arranged in series, with a smaller one at the front and then a main one. The pre-chamber of the FastBale produces two-thirds of the bale. As it reaches its preset density, crop then flows into the main bale chamber, allowing baling to continue without stopping.

The pre-chamber then opens, shifting the pre-formed bale into the main chamber, where it can be taken to its maximum size of 1.25m. When the bale has been made, the crop flow switches back to the pre-chamber, allowing baling to continue.

Net is then applied to the completed bale, the tailgate opens and it transfers on to the wrapper. All this happens seamlessly, helped by a wrapper frame mounted on a parallel linkage.

This means that the wrapper can be lowered to meet the completed bale as it rolls from the main chamber – there's no need for a complicated mechanical transfer system.

The result of all this cleverness is – potentially – the ability to wrap 100 bales an hour with six layers of plastic wrap. That's a prodigious output, and one that would bring a smile to the face of a farmer or contractor alike.

Vicon also points out that many of the components, such as the rollers and pick-up, are already used on the company's existing balers.

So there's nothing untested or high-tech.

When will it be on sale?

Baler product manager Tim Baker would not be drawn on production dates or availability. Like all manufacturers, Vicon wants to get all the bugs out the machine before farmers get their hands on them.

However, it sounds like there may be limited availability in a couple of years.

This article is from our news archive. As a result pictures or videos originally associated with it may have been removed and some of the content may no longer be accurate or relevant.

Get In Touch

AudlemOnline is powered by our active community.

Please send us your news and views using the button below:

Email: editor@audlem.org