What was it that persuaded me to go into business manufacturing wooden aircraft propellers? Several things really.

First, I flew an airplane which uses a wooden propeller.

Second, I had a friend that had made one and the thought occurred to me that anything he could do I could do.

Finally at that time we aviators had no choices in propellers as the only ones available to us were made by a French man Claude Evra.

So, in the time honoured fashion I bought a book.

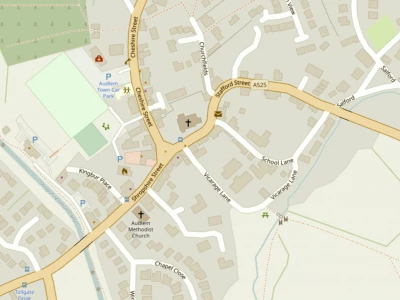

I had in the village a joiner's workshop and beneath it a well-equipped drawing office. From my book, I studied things like Diameter and Pitch and realised that to continue I needed a bandsaw, a planer, a large press and several measuring devices. Some of which I had to make.

However good fortune smiled on me and one day I received a visit from a man I did not know. He said "I have heard that you are making wooden props and I have had WW11 experience when I was directed to a company in Trafford Park Manchester with a team of joiners to carve Spitfire props and I have brought for you my tools which were made for me by a wartime toolmaker friend."

In those days the Spitfires had fixed pitch props which soon proved inadequate. This was followed by variable pitched props from America which gave increased performance in take off and climb.

Each propeller needs its own design drawing before any carving can begin and so I went to my drawing board and prepared my first design. I had decided that I would make first a prop which would drive my own aircraft.

Now, you can't just make bits for aircraft without any control. All such things have to be approved and tested. So, I sent a copy of my drawing to the authority and received a hesitant approval to proceed with the strict understanding that the prop when made must be examined and checked out before it was bolted to an engine.

It was made, balanced and finished. Stamped on the casing with idents for the manufacturer and the pitch and diameter.Examination completed and we were ready to bolt it in place and make ground runs.

So, I'm sitting on the end of the runway. I have bolted the prop to the engine and wire locked the bolts. The ground runs are good. The aircraft has been chocked and max power fed in.rev's read as they should. Oil pressure and temperature are normal and no noticeable vibration (on an aircraft the prop is also the flywheel and so it must be perfectly balanced).

When these are complete you reach a point when there is nothing left to do but turn the wick up and fly. This is the point when self reliance is Paramount. There is no one else to blame if the next few minutes go pear shaped.

Thankfully it worked and didn't, disintegrate. What fun!

I went on to design and carve many more, leading to the development of a copy carving machine which I had seen whilst in America. Some were carved for Europeans and had to be delivered strapped to the inside of the fuselage of Romeo Romeo.

Some were made for Microlite aircraft which were then in their undeveloped infancy. I also made many for the Baloonatics who used them on small mobile engines to inflate the balloons before lighting a gas fire under them.

About this time a new three-cylinder engine was being developed for a small aircraft to be made for Richard Noble the land speed record holder. The engine prototype was to be tested with a bench test run of I think several hundred hours. They needed a prop which would load the engine with sufficient work and also keep it cool enough to continue for the entire test.

The engine manufacturer and I had a heated discussion as to the dimension and pitch of this very experimental prop. We eventually agreed that I should design and make two. One to his suggestion and one to mine. I don't know now which proved the most successful.

It was about this time that I received an intriguing phone call from a company famous in the aviation world for making and marketing equipment for aerial re-fuelling. The company was founded by Sir Alan Cobham who became famous for his flying circus during the between wars period. Would I make them a very special prop to a design that they would bring to me.?

Yes of course I would, especially as the promised pay sounded good. They sent a car with the drawing from Wimborne Minster, Dorset.I reckoned little to the prop when I had made it, but they came by car to collect it and that I thought was that.

However, that was not that, because for several months they continued to order sometimes a couple of props a week many being variations of the first. They then gave me some dimensions and asked me to submit a design and all this while they sent cars to collect from me and would not tell me what this was all about. They wouldn't even tell me what engine it going to be fastened to.

However eventually my conversations with the firm did give me an outline of what they were doing with all these props. You may remember that during the defence of the Falklands it was necessary for the infantry to trot across miles of swamplands from Saint Carlos anchorage the 56 miles to Stanley where the Argentinians were bedded down.

When they arrived across these swamplands they were almost too fatigued to conduct the business in hand. After this hard lesson someone in the MOD must have thought what a good idea it would be if next time the infantry could fly. So, they gave Flight Fuelling "Cobham's" company a contract to design a microlite that would fold into a back pack and be thus carried into battle as required. My contribution was to provide several props for design changes until they got it right.I was never privy to the secrets but I believed that what they had tried to do was not possible.

The last prop I made for Cobham's was very short and quite the strangest shape. I could not imagine what could be gained by using it, but mine was not to reason why.I was therefore surprised when shortly after delivery of this oddity I received a phone call from the head of the design team who said ' Mr Farr this prop that you have sent us is developing more thrust than we have calculated is possible with the available horsepower. Will you tell me how you have done that.'

I didn't know what I had done.So what could I say to that. I couldn't think what to say, then inspiration hit me. "Well you see Professor we all have our little secrets don't we."

Why did I stop making props? Well that's another story...

Cheers for now,

Geoff

Click on Photo to enlarge

This article is from our news archive. As a result pictures or videos originally associated with it may have been removed and some of the content may no longer be accurate or relevant.

Get In Touch

AudlemOnline is powered by our active community.

Please send us your news and views using the button below:

Email: editor@audlem.org